In my previous Hydronic Heating Coil Replacement post, Jim asked about more information on my heating system. I’ve finally had the opportunity to collect some of that information and try to crunch the numbers. I can’t guarantee that any of what follows is correct – even after almost 5 years, I’m still learning about my heating system as it was installed by the previous owner of my house.

My house is a 1½ story, approximately 1900 sq-ft of finished space and another 600 sq-ft of un-finished basement space.

My source of hot water is a Polaris Natural Gas hot water tank, model PR-100-34-2NV. This is a 34 gallon tank that is capable of 100k input BTU per hour and 129 GPH recovery rise to 90°F.

To pull the water from the tank through my hydronic heating coil, I have a Taco 006 Cartridge Circulator.

It’s a rather cold day today so the system has been on a fair bit. This is good for getting ballpark temperature readings. For all of my temperatures, I’m using a Mastercraft Digital Temperature Reader which happened to be on super sale last week. It’s supposedly accurate within ±2°F at room temperature. You do have to keep the reader as close as possible to the subject though or you will get poor results. I tried to keep within 1 inch at all times.

The Numbers

The output air temperature is 100°F (37.8°C) at one of my main floor forced air registers. This is probably the most direct run in the house and was also the hottest of the few I checked.

In the basement I took a few readings at different points in the system. Now, all of the copper pipe used in the system is ¾ inch and it appears that the heat does not transfer quite as much.

The Polaris hot water tank is set to 60°C (140°F). At the hot water tank outlet, the copper surface temperature is 120°F (48.9°C). Just before the Taco 006 circulator pump, the copper is 100°F (37.8°C). The circulator pump itself has a surface temperature of 160°F (71.1°C) (!).

Just before the hydronic heating coil in the plenum, the surface temperature of the ¾ inch copper pipe is 85°F (29.4°C) and after going through the coil the output is 81°F (27.2°C).

The hot water tank inlet is 90°F (32.2°C).

This is all in my unfinished basement area where the ambient temperature is 64°F (17.8°C).

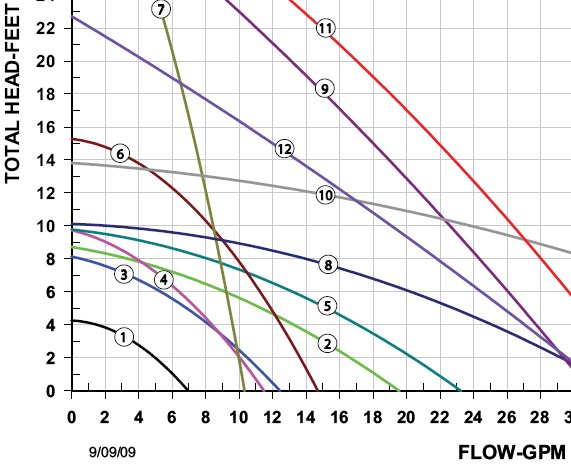

Based on the data sheet (and the graph shown above) the Taco 006 Circulator is moving between 7 and 8 GPM in my installation (4 foot lift from the tank outlet to the ceiling where the forced air unit is mounted). The 006 is represented by the blue curve with the number 3.

Analysis(?)

This would suggest that there is a 30°F (16.7°C) drop in the water temperature. Unfortunately, that’s really just a SWAG because measuring the copper surface temperature is not going to be a linear delta to the water temperature.

Oh, and I’m really not sure why the Taco 006 circulator had a surface temperature of 160°F. It does feel quite hot to the touch but it shouldn’t be more than the 140°F water going through it. Maybe the surface is too shiny for the temperature reader to get a correct value.

Jeff

I put some comments on the other page.

As for your numbers, I’m guessing the Polaris 140°F setting is pretty accurate. If the temp at the hot water tank outlet the copper surface temperature is 120°F (48.9°C), I suspect the 20°F drop is based mostly on copper resistance with a little based on heat loss to the cooler ambient air. On the return/inlet side, there’s probably some heat transfer from the tank to the pipe to boost the temp even if the water in the pipe is cooler.

As you approach the pump and coil and then after the coil, I’m guessing the additional temp drop is more due to the ambient air temp than copper resistance. (The high temp at the pump could be heat from the pump motor itself, which the hot water wouldn’t do much to cool.)

I was surprised that the difference between the intake and output temps at the coil itself are not even 5°F. but the temps a few feet away may be more indicative. I suspect the fan blowing on the coil reduces the intake and outlet temperatures even more.

I agree with your guess that there’s about a 30°F difference between water out of the tank and back into the tank.

Another thought on getting more accurate temps. What if you put a foot (30cm?) of foam pipe insulation on the pipe at various spots for a couple hours before measuring? If you slide the foam away right before you measure, you might get a more accurate reading of the actual water temp by eliminating most of the loss to the ambient air. Just a thought.

By the way, do you know if your heat bills are higher, lower or about the same as those of neighbors with conventional heaters in similar houses?

Thanks again for the help.

Jim

There is definite heat transfer from the tank to the hot water inlet. One of the problems we have with this tank is that it wasn’t installed properly (according to the Polaris installation manual). There were no heat traps installed on the domestic hot water outlet or on the domestic cold water inlet. We often get blasts of hot water coming out of our cold water tap in the kitchen (which is directly above the hot water tank and thus the shortest run).

Unfortunately fixing that issue is still on my todo list. ;)

I agree that the 5°F delta between the inlet and outlet on the coil was unexpected. With surface temperatures it’s rather difficult to get a decent idea of temperature. I have to let the system run long enough to get to “steady state” but I don’t know what “long enough” is. Maybe on the next really cold night when it runs almost all night I’ll see if I can get some more readings.

Oh, the pipes are almost completely insulated with regular grey ½ inch thick pipe insulation. None of it is completely sealed though so I was just moving it out of the way to take readings.

As for my heating bill, I’ve been trying to determine for a while if it’s better or not. I believe I use a fair bit less natural gas than a standard furnace/hot water tank installation but I might have a higher electricity usage than a typical furnace. The system doesn’t super heat the air (it’s only 100°F) so my ½ hp blower probably runs a lot longer than in a “standard” furnace.